How are nicotine pouches made?

- The main content of nicotine pouches (tobacco-free white snuff) is cellulose, which is extracted from tree pulp. The most common for nicotine pouches is cellulose made from spruce, where the trees are “ground” down to the pulp you are used to seeing in the white prills.

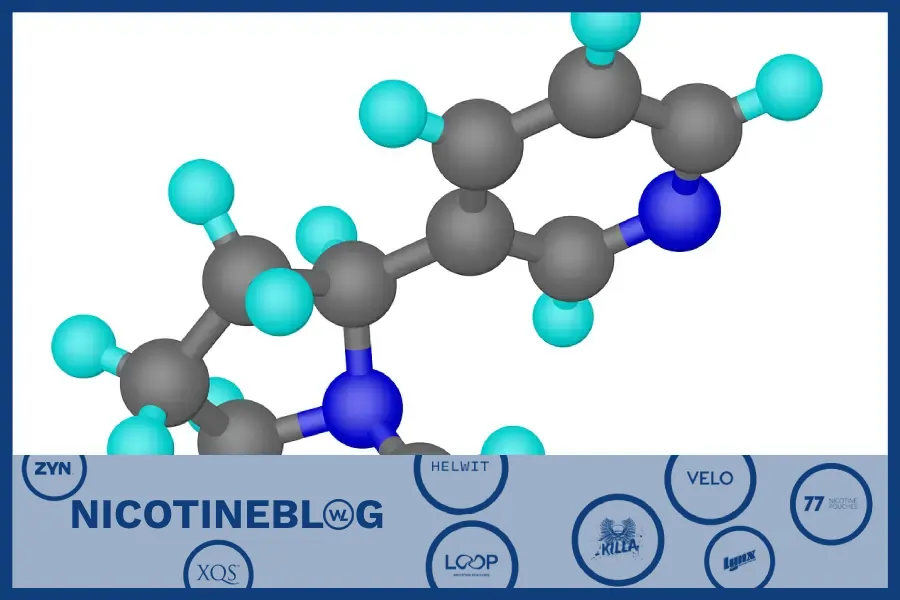

- The second stage of manufacturing is the mixing of ingredients where nicotine, flavorings and other additives are blended. Different products have different contents but common ingredients include thickener (E401), filler (E460), stabilizer (E415), salt, acidity regulator (E501) and sweetener (E950). Other substances may also be present. For the full list of ingredients, read the back of your box.

- Once the batch is mixed, it is time to fill the paper and thus create the prills. Different types of machines are used for this but the general principle is the same. The paper that forms the outer layer of the prill is generally made of paper or a type of nylon. The paper gets a dollop of the mixed pulp, and then the edges are ‘welded’ together using high heat to keep the pulp inside.

- Once the prills are welded, they go into their box, which is then labeled on all sides. The appearance of these labels is regulated by the Public Health Agency, which updates these requirements regularly, as you as a consumer will have noticed.

Read more about the production of nicotine pouches

here